Robotics Simplified

Empowering developers, innovators, startups & OEMs

Development tools which are meant for desktop application development and embedded system development are being repurposed for robotics.

With black box solutions, developers don't have modular building blocks to collaborate & build innovative robotics solutions of their own.

Building robotics solutions requires highly skilled developers, working exclusively in the domain. That's only a handful of developers.

The first-ever comprehensive set of software libraries and tools for robotics - to enable every developer to build smart robotics solutions, right from a toy to an industrial robot. It's a complete package of software, solutions, knowledge repository and community support that you need to power your robotics innovations.

It just takes an innovative mind and a wilful technologist to develop a robotic solution

A standardised system for reliable real-time data sharing

A repository of reliable algorithms and tools for efficient development

An Integrated Development Environment that makes it easy to build, deploy, monitor and manage robots

A visualization aid that allows testing out algorithms virtually without actual hardware

PCF is relevant for every industry domain where it can be utilized for building robotics applications and solutions across business processes and verticals.

Manufacturing

Automotive

Logistics & Supply Chain

Metallurgy

Product Design

FMCG

Electrical & Electronics Manufacturing

Oil & Gas

Energy

Security & Surveillance

Pharmaceuticals & Chemicals

.png)

Retail & Lifestyle

Military & Defence

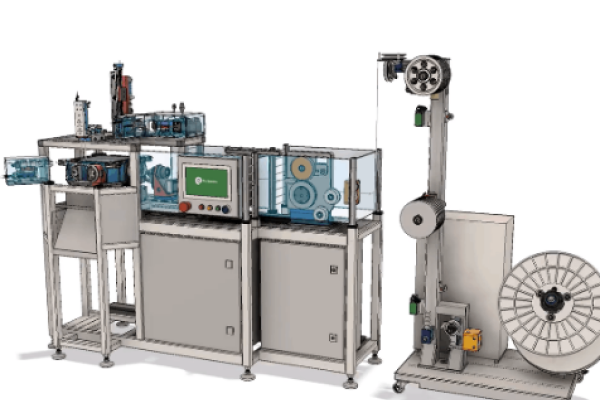

An integrated robotic solution to combine the process of coiling, cutting, taping and tagging a shock tube detonator - reducing cost, increasing efficiency and improving throughput.

A leading explosive manufacturer wanted to integrate the process of coiling, cutting, taping and tagging a shock tube detonator into one machine. The existing process was sequential, semi-automatic, and labour-intensive and the existing solutions could not deliver on the requirement, nor were they customizable enough to enhance.

| Complete control over the Bill of Materials, mechanical design and manufacturing process | Future customizations possible | Level 1 support and maintenance could be handled internally |

| 3x reduction in the total cost of ownership | 2x improvement in throughput | 10x faster and more efficient development |

An innovative vehicle control unit (VCU) for EVs that was customized to remove technical gaps and was owned and managed by the EV manufacturer, not a third-party OEM - reducing manufacturing cost and time to market.

An electric vehicle manufacturer wanted to build a vehicle control unit (VCU) for their EV, giving them complete ownership of the VCU and removing dependency on a third-party OEM. They were able to create their own product thereby reducing manufacturing costs per vehicle with the potential to sell the VCU as a product to other EV manufacturers.

| Developers, with minimal knowledge, could visually program the VCU as per their needs | 6x reduced time to market | 10% of overall manufacturing cost per vehicle saved |

Find out how you can use PCF to develop your solution. Learn more about this in your free call.